Sectors

Intramark Ltd.

Sectors

Construction

In the construction sector, sealing elements such as rotary shaft seals and hydraulic seals are integral to the reliable operation and maintenance of heavy-duty machinery, including cranes, excavators, and concrete mixers. These components are essential in maintaining the closed integrity of hydraulic and powertrain systems, effectively preventing oil leakage and ingress of harmful contaminants such as dust, dirt, and water.

High-performance sealing solutions directly contribute to operational safety, reduce unplanned maintenance, and extend the service life of critical equipment, ensuring continuous performance in harsh on-site environments.

Agriculture

The agricultural industry relies heavily on robust and durable sealing solutions to ensure the uninterrupted functionality of a wide array of agricultural machinery and irrigation systems. From tractors and harvesters to pumps and sprayers, seals and gaskets serve to shield critical components against dust, moisture, mud, and chemical exposure.

Precision-engineered sealing systems improve equipment longevity, minimize fluid leakage, and safeguard mechanical performance under demanding field conditions—supporting the reliability and sustainability of modern agricultural operations.

Lifting technology

In lifting technology applications—encompassing cranes, forklifts, hydraulic lifts, and aerial work platforms—seals and oil seals are fundamental to the performance and safety of hydraulic actuators and drive systems. These components maintain system pressure, mitigate leakage risks, and block external contaminants from compromising the machinery.

Reliability and load-handling precision in lifting equipment are critically dependent on optimal sealing performance, which supports not only operational efficiency but also compliance with safety standards in material handling and construction logistics.

General Machinery

Sealing technology plays an indispensable role in the mechanical engineering and industrial machinery sectors, ensuring operational continuity and efficiency across diverse systems, including engines, gear units, compressors, CNC machines, and hydraulic presses.

High-quality seals mitigate wear, eliminate fluid loss, and maintain the integrity of both dynamic and static systems. Their use directly supports preventive maintenance practices, reduces operational costs, and increases machinery uptime—factors vital to both production continuity and quality assurance.

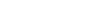

Automotive industry

In automotive engineering, the implementation of advanced sealing solutions is critical for the performance and longevity of internal combustion engines, transmissions, differential systems, and hydraulic mechanisms. Seals ensure system enclosure, effectively preventing lubricant loss and ingress of contaminants that may impair performance.

From original equipment manufacturing (OEM) to aftermarket services, premium-grade sealing components contribute to overall vehicle reliability, energy efficiency, and environmental compliance by upholding the integrity of key mechanical systems under varying thermal and mechanical loads.

Chemical industry

Seals and gaskets deployed in the chemical industry are subject to some of the most demanding operational environments, often involving corrosive fluids, extreme temperatures, and high-pressure systems. These components are utilized in reactors, dosing systems, centrifugal pumps, and complex pipeline infrastructures to ensure total process containment and prevent hazardous material leakage.

To meet strict industry regulations, our seals are manufactured from chemically inert, temperature-resistant elastomers and polymers—ensuring long-term safety, environmental protection, and reliable chemical processing continuity.

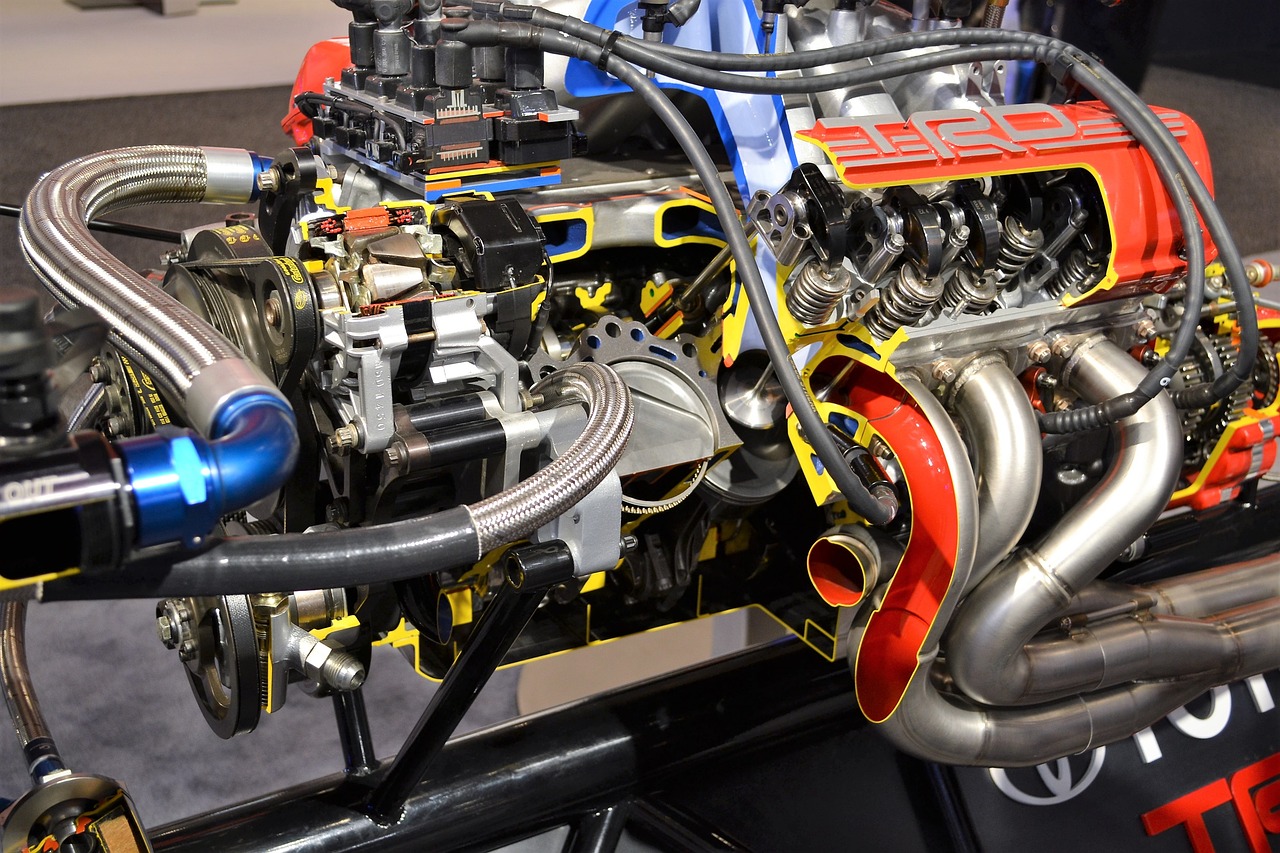

Plastic industry

In the plastics processing sector—including extrusion and injection molding operations—sealing systems must withstand high thermal stress, repeated cycles, and exposure to process chemicals. Seals in this field ensure the tight operation of hydraulic circuits, compressor systems, and mold components.

We provide specialized polymer-based sealing solutions engineered for enhanced durability and precision, thereby ensuring uninterrupted production, reduced energy loss, and longer equipment lifespan in high-output manufacturing environments.

Pharmaceutical

The pharmaceutical industry imposes stringent standards for hygiene, sterility, and process integrity—making high-performance sealing solutions essential across production, mixing, transfer, and packaging systems. Seals in this sector must meet regulatory requirements for material biocompatibility, chemical resistance, and cleanability.

Our pharmaceutical-grade seals are produced from FDA- and USP Class VI-compliant materials, ensuring maximum purity and reliability. They play a critical role in preventing contamination, maintaining clean-in-place (CIP) and sterilize-in-place (SIP) compatibility, and upholding product safety across all stages of pharmaceutical manufacturing.